Tooling

Full integration of all stages from planning, design, simulation with state-of-the-art software, mold production, production testing and final execution.

All in one place with more than 50 years of experience in the development and construction of injection molds, bi-injection and stamping tools, with a guarantee of over one million cycles.

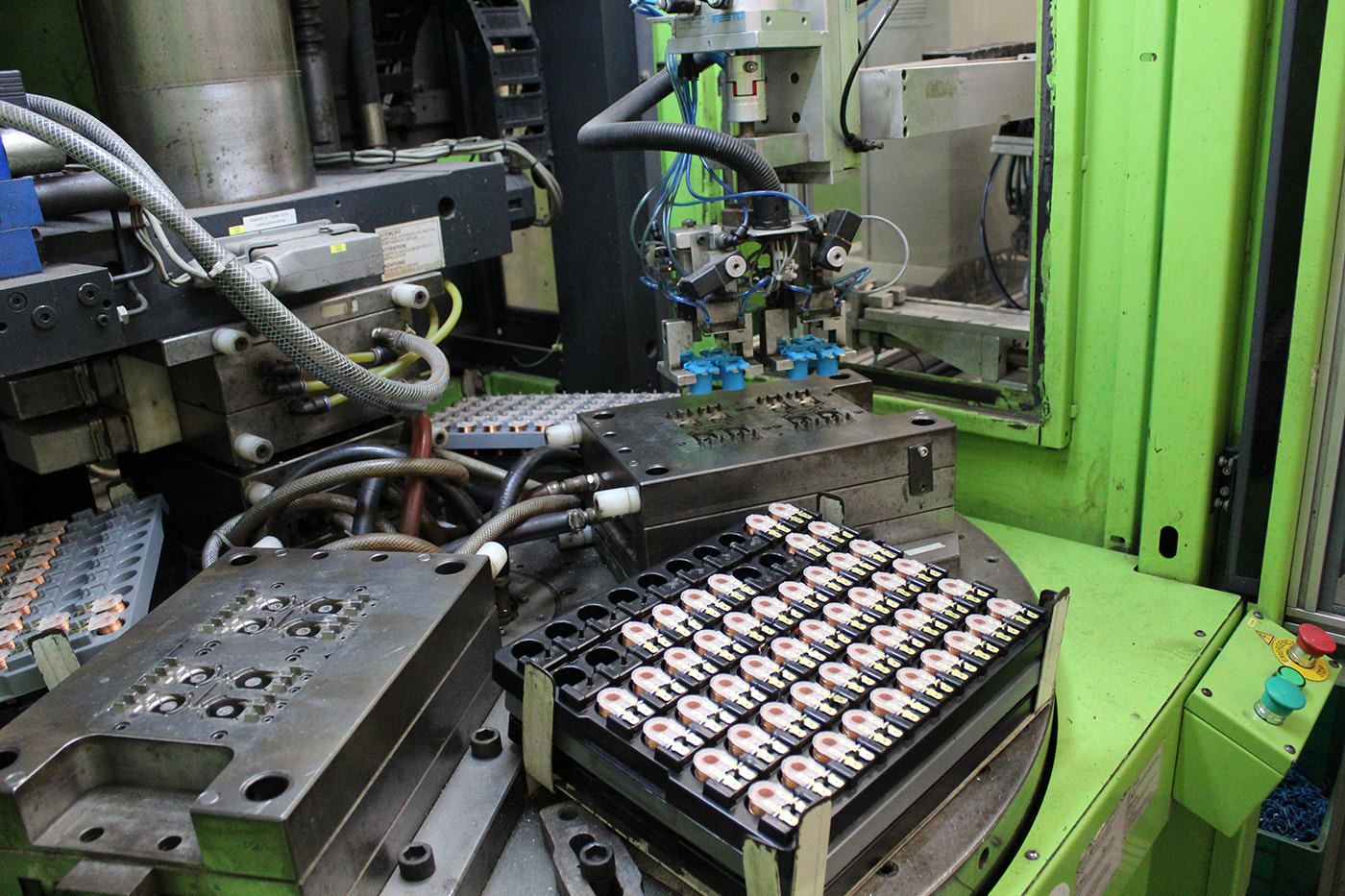

Engineering Thermoplastic Injection

We are specialized in thermoplastic injection services and have a modern industrial complex with technical and modern facilities and state-of-the-art injection molding machines.

Working in complete harmony with the client in the development of new products and projects, we guarantee the highest degree of precision and quality, from strategic partnerships for the supply of noble raw material to the final product, passing through the development of molds and processes.

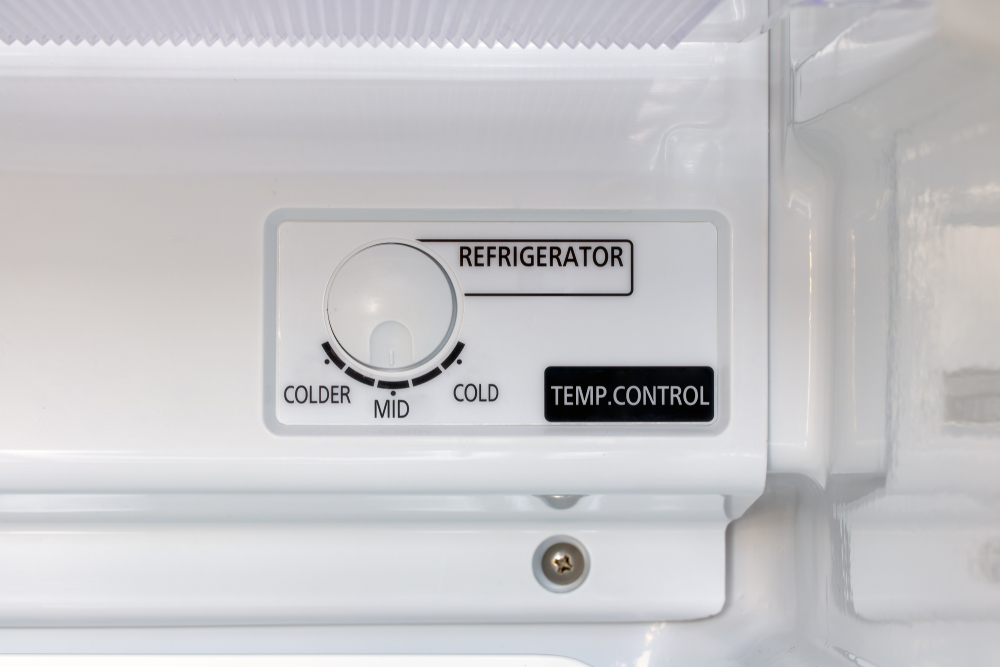

Press Shop

Located in an exclusive area within the Industrial Complex, our stamping shop has been producing, with excellence, components with complex geometries and diverse characteristics with Kown how for the white goods and automotive segment, for over 50 years.

Wide range of machinery, with eccentric presses ranging from 35 to 200 tons, able to stamp components from 0,15 to 3,00 mm thick. Also counting on the Bihler process, which allows us to stamp and weld components in a single process, meeting the various needs of the current market.

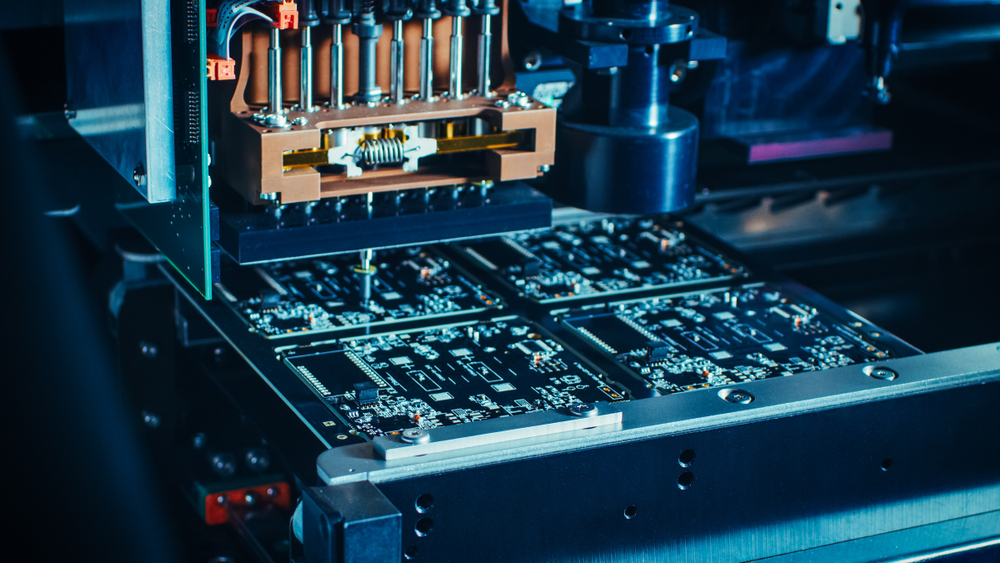

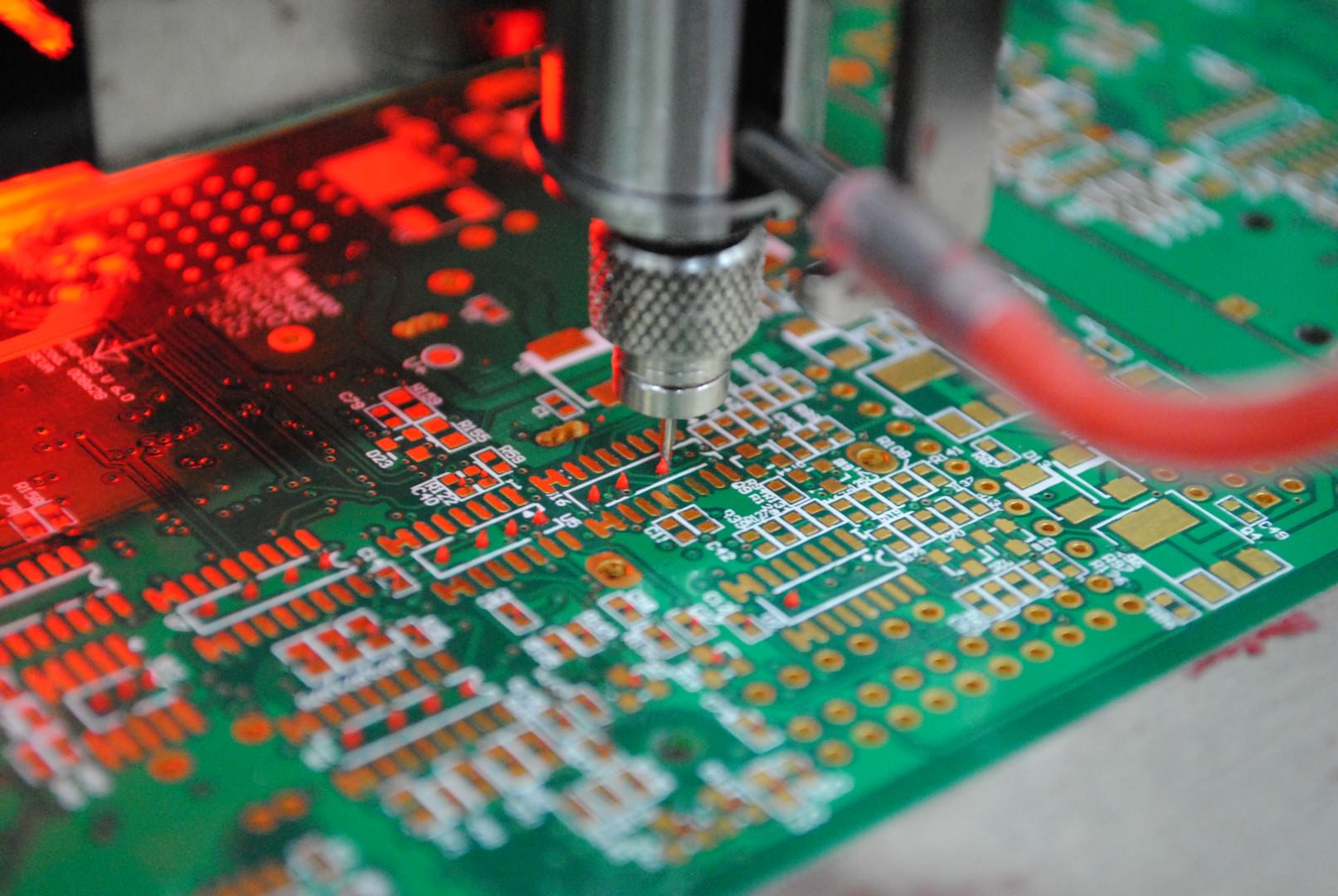

Electronics

It has over 20 years of experience in the market for original and replacement electronic boards, electronic solutions for the most diverse types of applications, with extensive domain and knowledge of SMT and THT processes.

For the SMT process, we have assembly lines with a high level of automation, from loading and unloading components, applying and checking the quantity of solder paste or adhesive through SPI, to inspecting the components at the end of the line using AOI.