Engineering Thermoplastic Injection

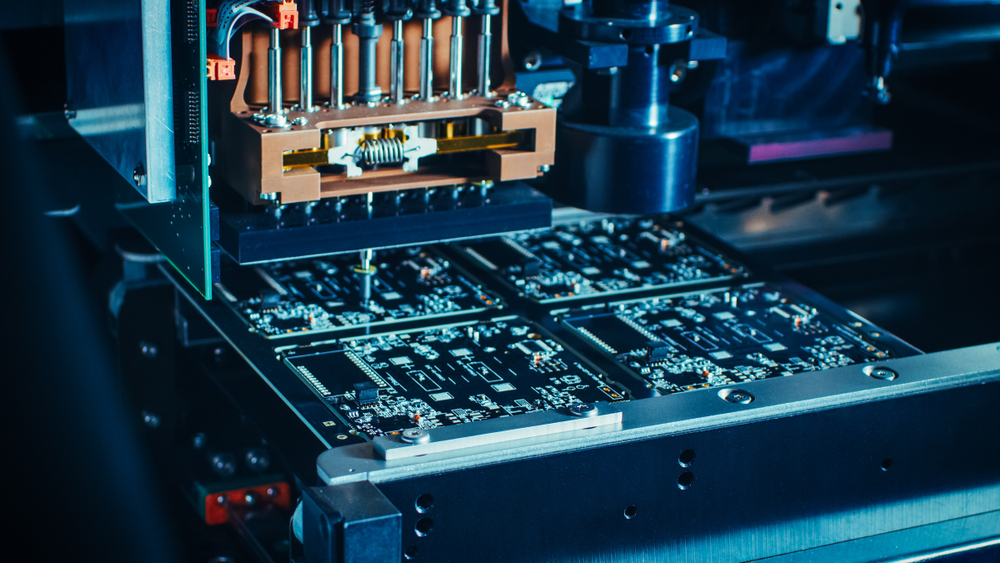

We are specialized in thermoplastic injection services and have a modern industrial complex with technical and modern facilities and state-of-the-art injection molding machines.

Working in complete harmony with the client in the development of new products and projects, we guarantee the highest degree of precision and quality, from strategic partnerships for the supply of noble raw material to the final product, passing through the development of molds and processes.

Our philosophy is based on "quality and guarantee of services provided with total satisfaction of our customers", for that, we provide, in addition to the accumulated experience of more than 50 years in the engineering plastics industry, the collaboration of specialized professionals working in technical installations and modern, with 1st generation equipment, with computerized injection molding machines capable of monitoring the entire injection process and automatic feeding of plastic resins and thermoplastic injection processes.

We currently produce a wide variety of thermoplastics, including PA (Polyamide/Nylon), PBT (Polybutylene terephthalate), PP (Polypropylene), PC (Polycarbonate), POM (Polyoxymethylene/Acetal), PPA (Polyphthalamide), PPS (Polyphenylene Sulfide/Techtron/Ryton), TPU (Thermoplastic polyurethane), Small businesses (Thermoplastic elastomer) with different amounts and types of filler (Fiberglass, phosphor, flame retardant, mineral filler, talc, UV and etc...)

Injection cells equipped with:

- Various injection molding machines from 45 to 180 tons, including bicomponent equipment and rotating plate

- Moretto gravimetric feeders for mixing raw materials, masters and additives

- Dehumidifiers

- overhead cranes

- Shelves with drawers for storing molds

- Chiller

- Software for production monitoring, with online OEE annotation

- Sequential injection control for sequenced hot runner process (multiple nozzles)

- Centralized raw material feeding, with vacuum and raw material consumption control via software

That's why we have large capacity to produce the various types of products, with different raw material compositions and dimensions.

From complex components that require over-injection processes, to high-volume items. Always ensuring robust, capable and efficient processes.

Doubts? Contact us!

If you want to know more about our automotive sector or white goods, get in touch! Our specialists are on hand to assist you.