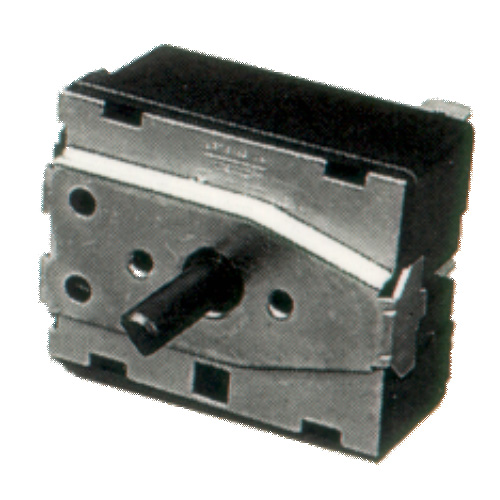

Electromechanical Controllers

Technical specifications

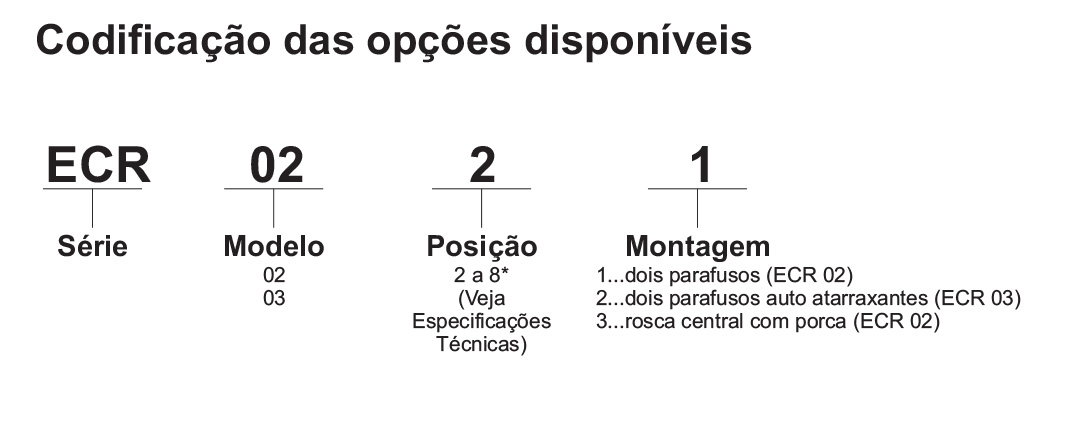

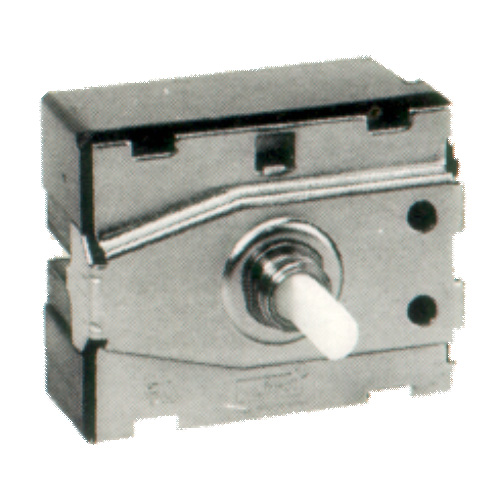

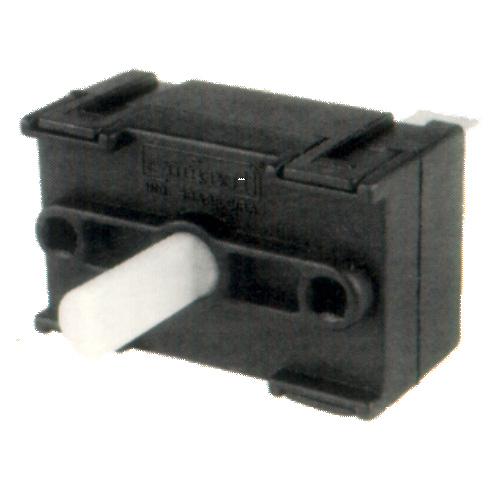

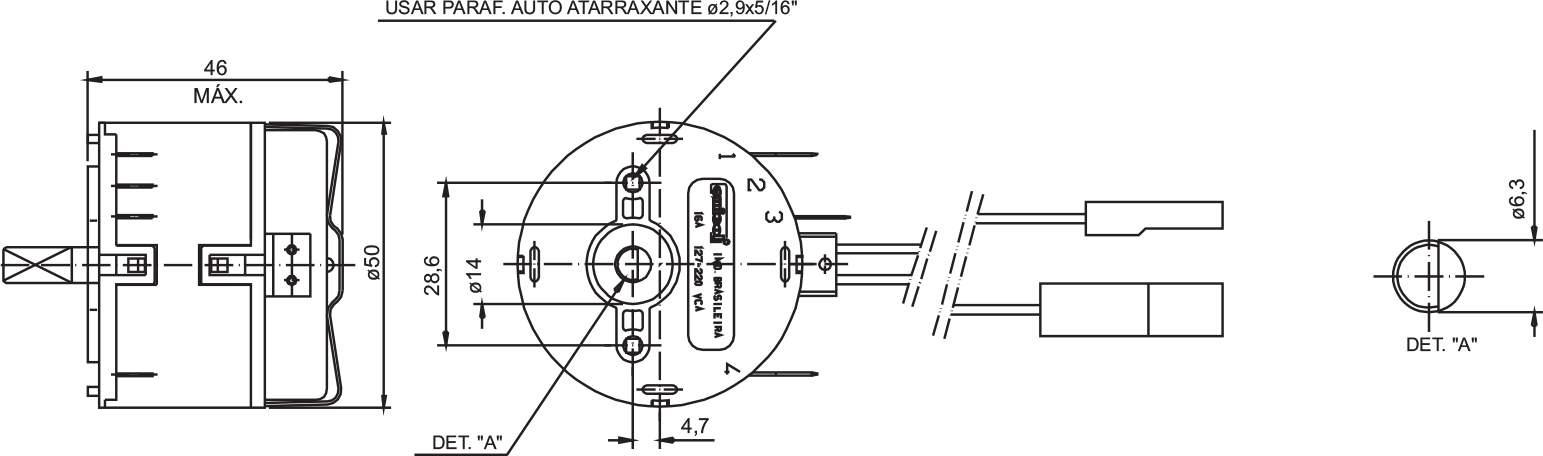

ECR series

Materials:

* Body: thermoset (ECR 02) thermoplastic (mod. ECR 03)

- Cam: thermoplastic / metallic

- Cover: galvanized steel (mod. ECR 02) thermoplastic (mod. ECR 03)

- Terminals: brass / copper

Recordings: according to customer specifications

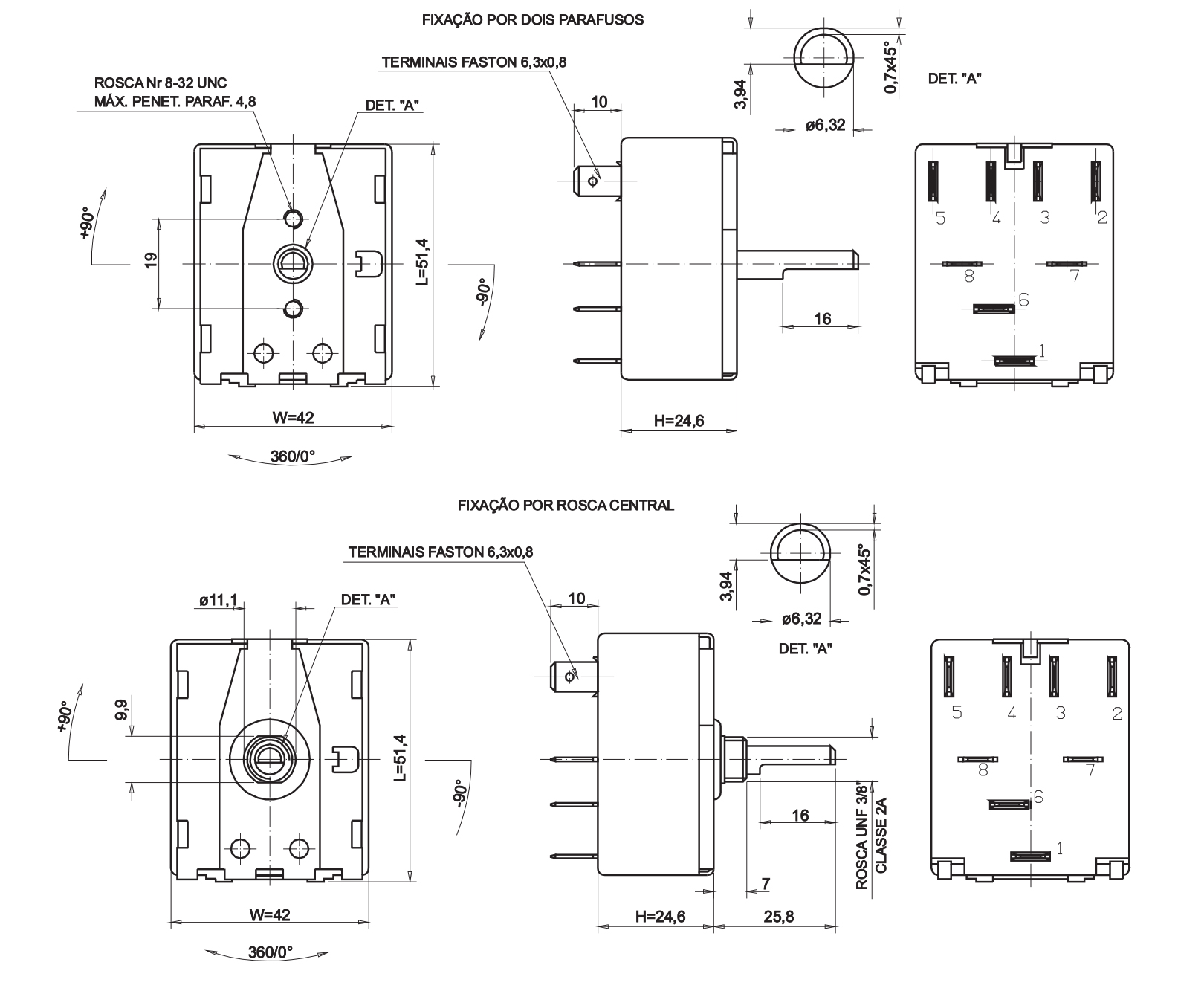

Fixation:

- two screws (Nr 8 - 32 UNC) (mod.ECR 02)

- central thread (3/8"UNF) with nut (optional) (mod. ECR 02)

- two self-tapping screws Ø 3,5mm (mod. ECR 03)

Number of positions:

- 2 to 8 (mod. ECR 02)

- 2 to 4 (mod. ECR 03)

Electric scheme:

- Model ECR 02 (see page 4.3): according to customer specifications

- Model ECR 03 (all can be unipolar or bipolar): ON-OFF / ON-ON / ON-OFF-ON

Current:

- up to 25A - 240Vac - 1Hp 120Vac; 2Hp 240Vac (mod. ECR 02)

- up to 16A - 240Vac - resistive load (mod. ECR 03)

Useful life: > 6.000 operations

Dielectric strength: 1.500Vac - 1 min.

Terminal Type: Faston 6,3mm

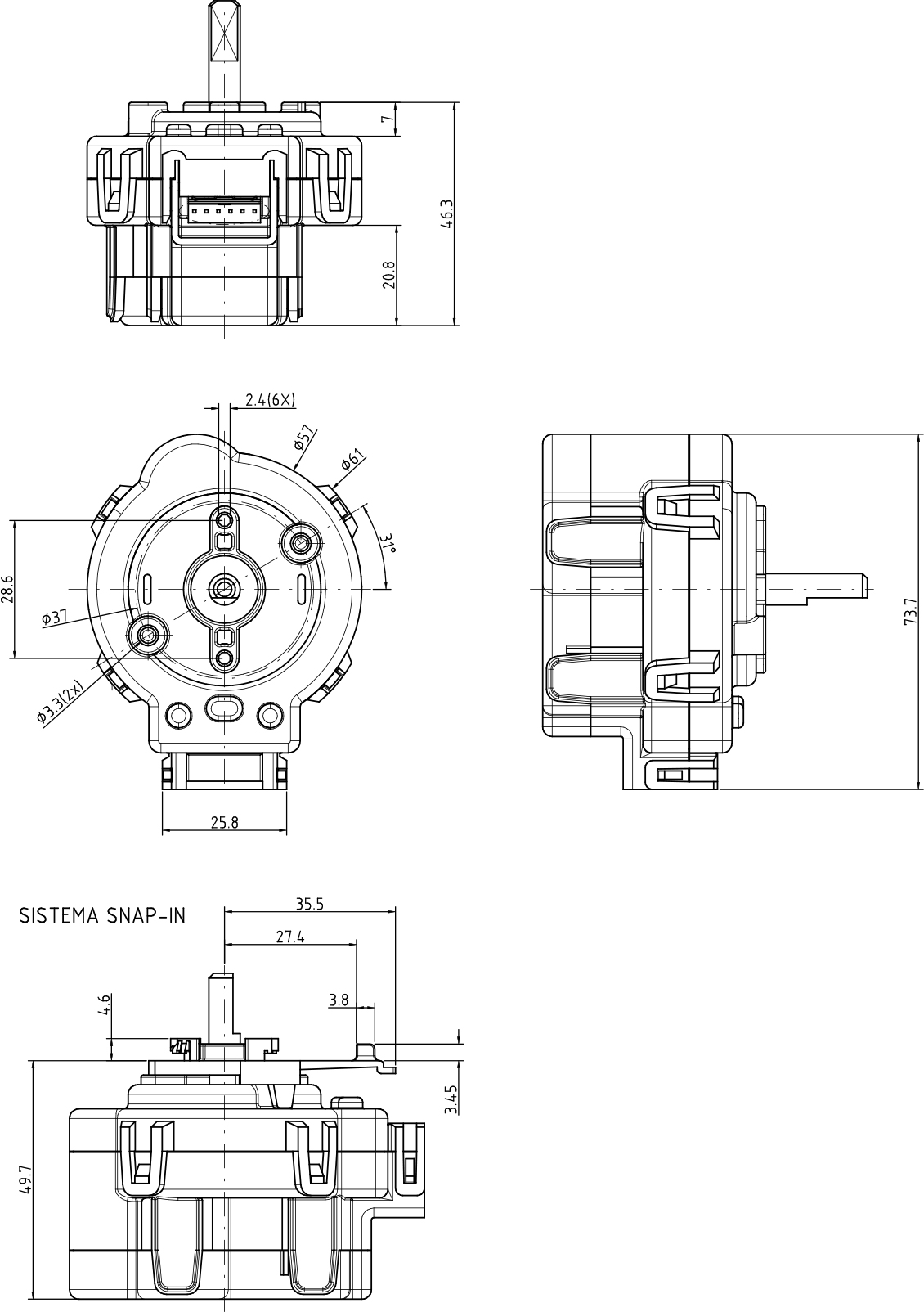

EMC Series (Motorized Contact Encoder)

Materials:

- Body and cam: thermoplastic

- Terminals: brass

Recordings: according to customer specifications

Tensão of the engine:

- 110/120 Vac - 60 Hz

- 220/240 Vac - 60 Hz

- 220/240 Vac - 50 Hz

Electric scheme: according to customer specifications

Switching the terminals: 24 Vdc / 50 mA Types of Terminals: Faston 2,8 mm Terminal treatment: golden Operating Temperature: 0 to 70°C

Useful life: > 5.000 cycles

Number of selectable positions: 16

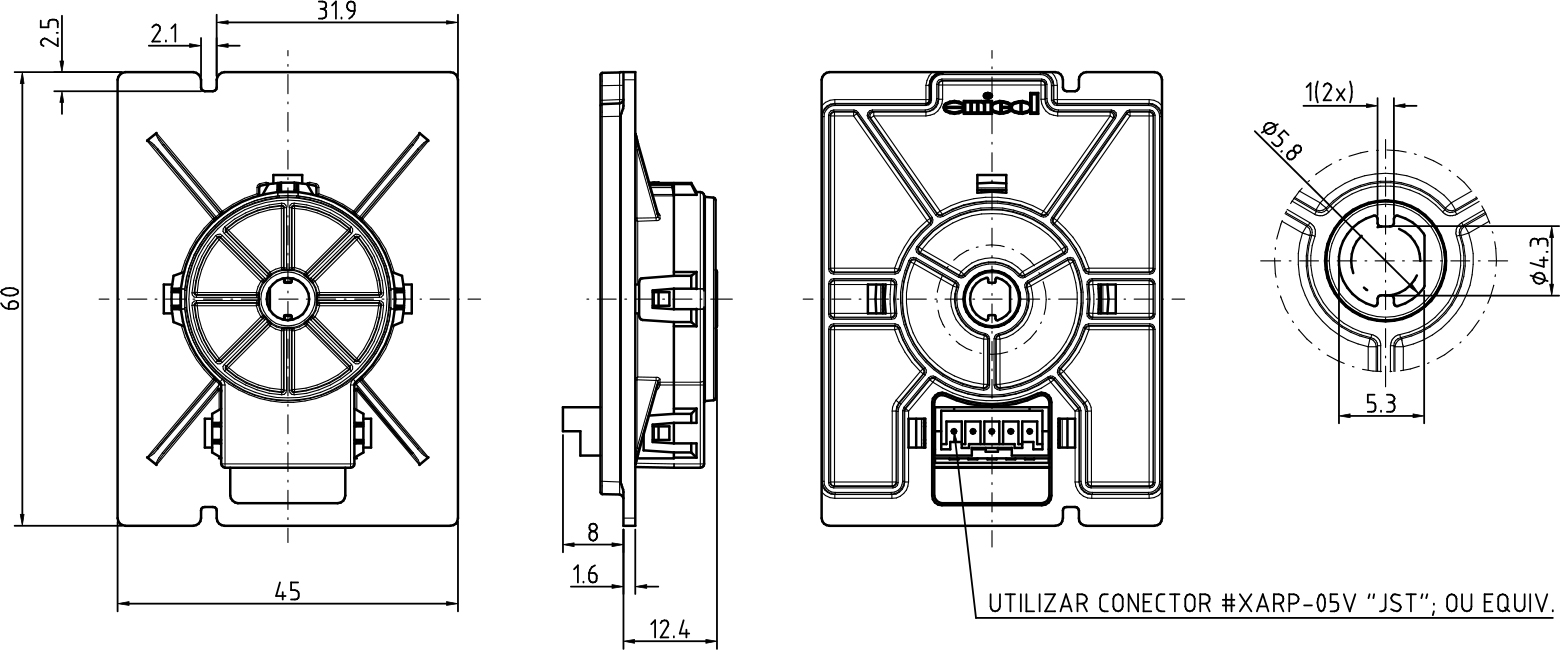

EMO Series (Optical Motorized Encoder)

Materials:

Body and cam: thermoplastic

Terminals: brass

Recordings: according to customer specifications

Maximum voltage / supply current: 12V/60mA Terminal for connector: 6-way AMP #171822-6, or EQUIV Terminal treatment: tin plated

Useful life: > 100.000 cycles

Functional Characteristic: Optical contact switching system, operates both clockwise and counterclockwise.

Number of selectable positions: 16

EEC Series (Contact Static Encoder)

Body: Thermoplastic

Recordings: As specified customer Dielectric strength: Minimum 100 Vac Axial torque: 0,07 to 0,11 Nm

Rated voltage/current (contacts): 5Vdc / 1mA

Useful life: 15000 cycles (7500 cycles in each direction of rotation)

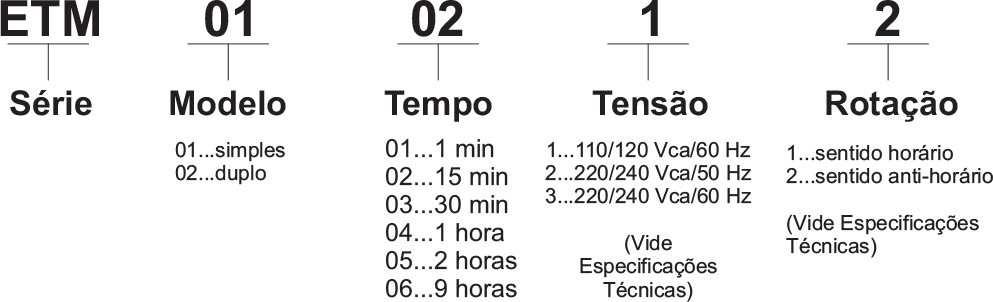

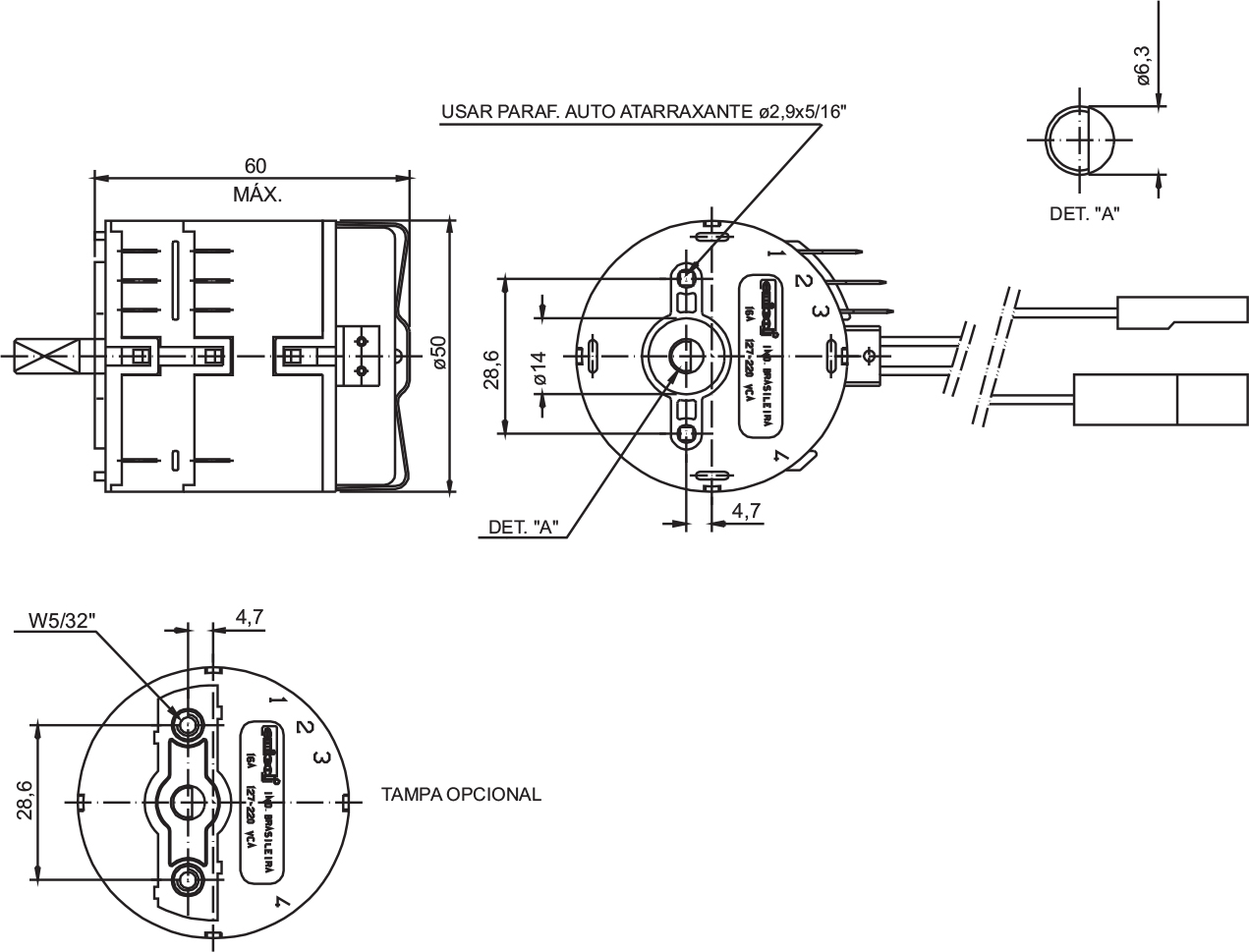

ETM Series (Electromechanical Timers - Timers)

Materials:

- Body: thermoplastic

- Cam: thermoplastic

- Terminals: brass, phosphor bronze

Operating Temperature: - 10°C to + 85°C

Fixation: In panel via two screws W 5/32"x 1/4" or M 4 x 6mm

timing: Standard models: 1 minute, 15 minutes, 30 minutes, 1 hour, 2 hours and 9 hours. Other timings on request

Sense: Clockwise or Counterclockwise

Electrical schematic and time switching diagram: Several possibilities, on request.

Food:

- 110/120 Vac - 60 Hz

- 220/240 Vac - 60 Hz

- 220/240 Vac - 50 Hz

Contacts:

Up to 3 contacts (ETM 01) - 2 normally open (NO)

- normally closed (NF)

Up to 6 contacts (ETM 02) - 4 normally open (NO)

- normally closed (NF)

Maximum current: NO Contacts: 127/230 Vac - 16 A NC Contacts: 127/230 Vac - 1A

Lifespan: > 10.000 operations

Dielectric strength: 1.500Vac - 1min.

Terminal Type: Faston 4,8mm x 0,5mm

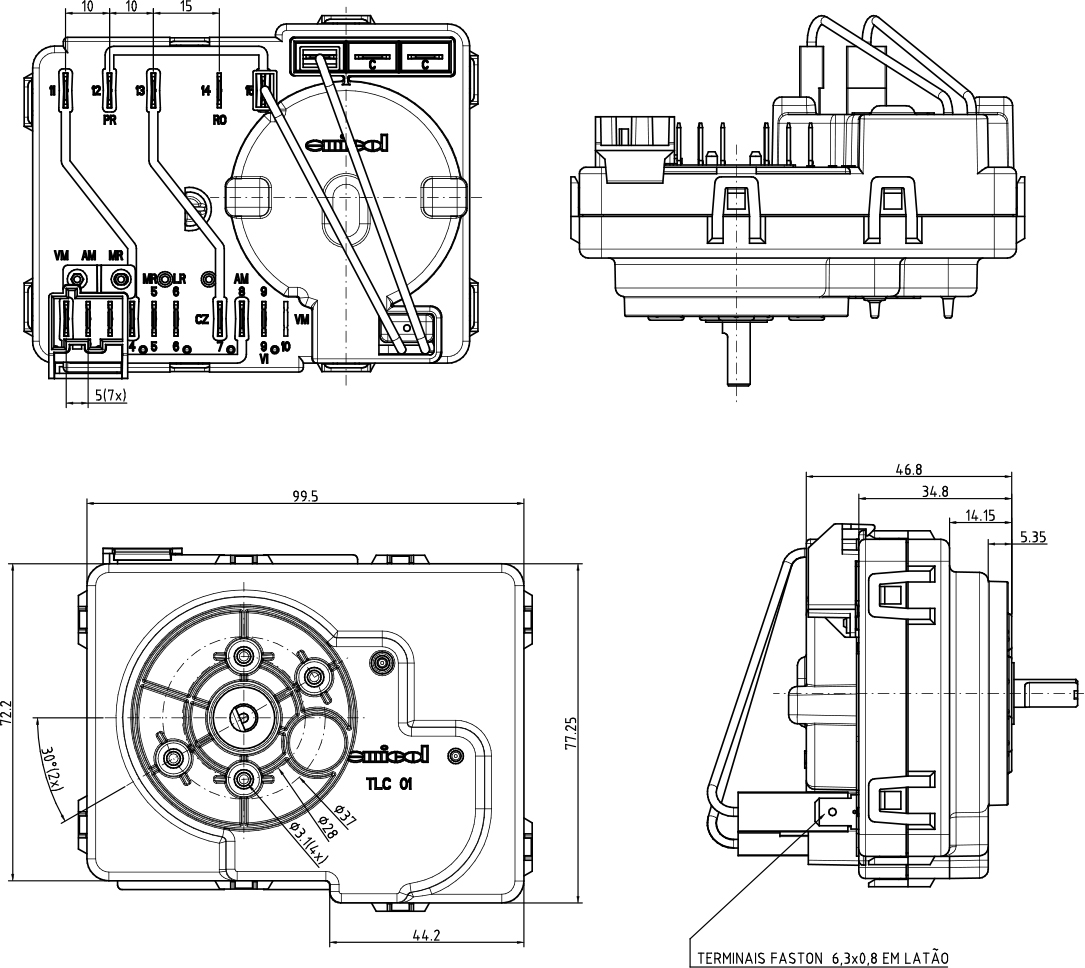

TLC series

Materials:

- Body and cam: Thermoplastic

- Terminals: Brass

Electric current:

- 127 Vac - 15,8 ± 0,5 A

- 220 Vac - 10 A ± 0,5 A

Recordings: As per customer specification Operating Temperature: 0 to 70 ° C Timing: On request

Rotation sense: Timetable

Useful life: > 3.650 cycles

Dielectric strength: 1.500 Vac - 1 min

Terminal Type: Faston 6,3x0,8

Electrical schematic and switching diagram: Various possibilities including engine reversal, on request.

Food:

- 110/120 Vac - 60 Hz

- 220/240 Vac - 60 Hz

- 220/240 Vac - 50 Hz

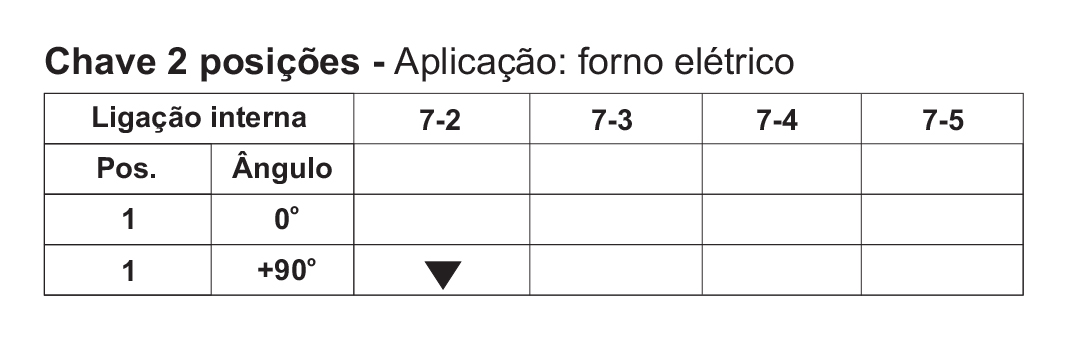

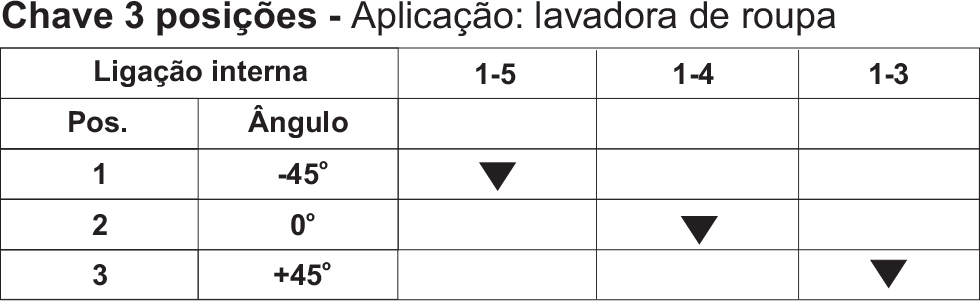

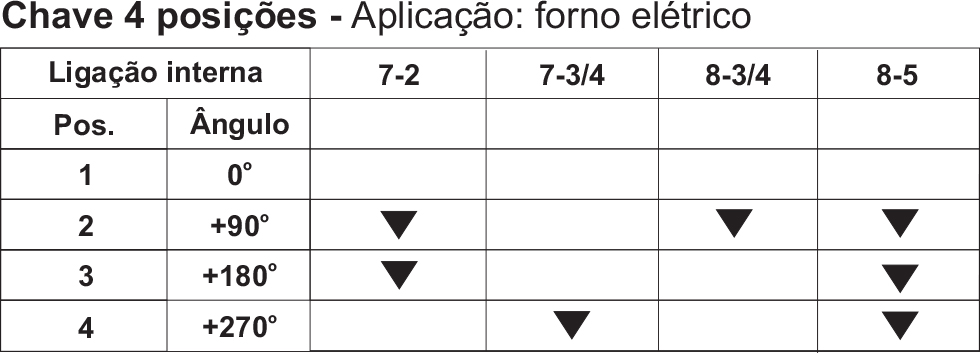

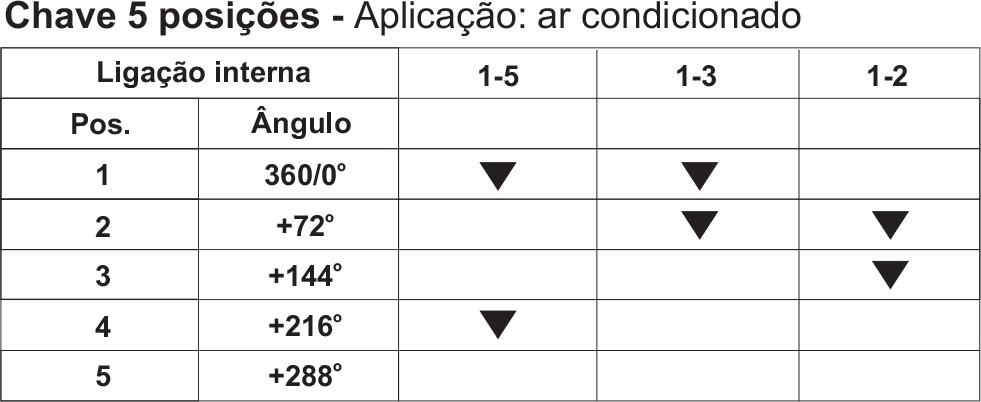

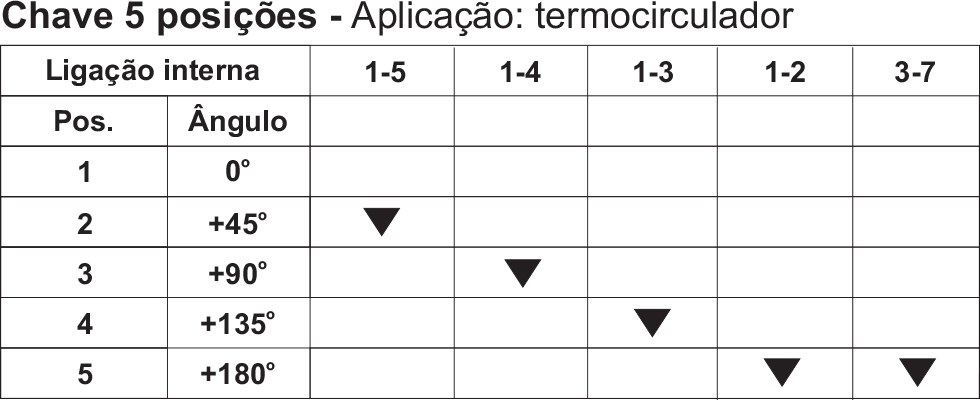

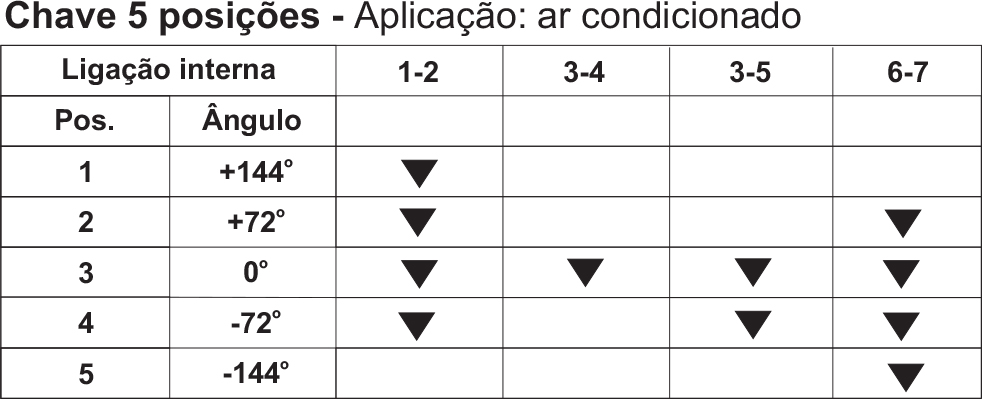

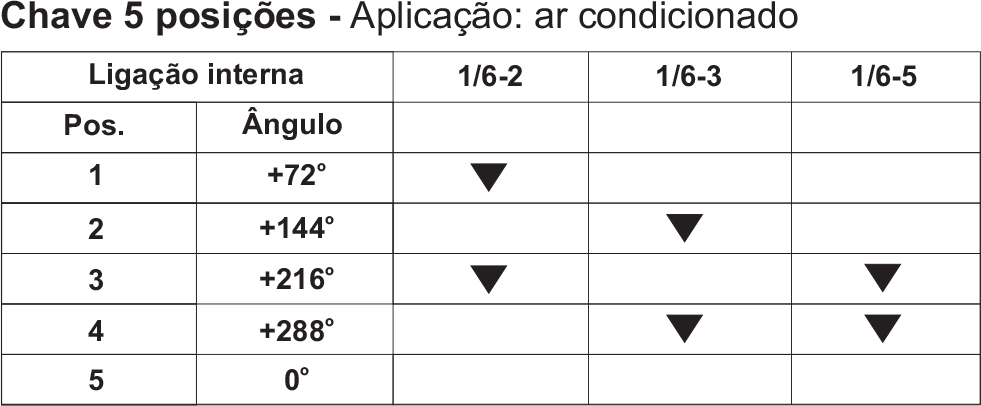

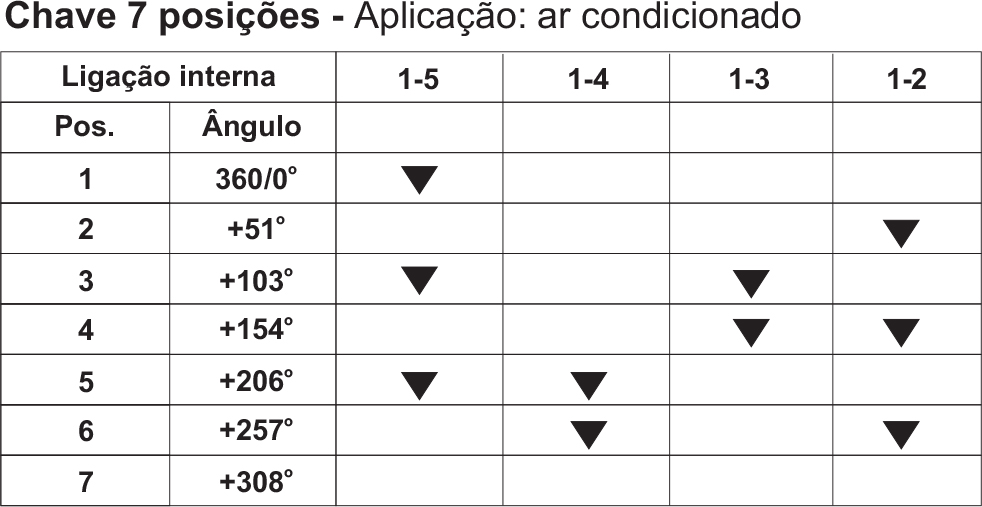

Electrical diagrams of some typical applications already developed Compact Rotary Switch (mod. ECR 02)

Checklist for samples and quotations

ETM and TLC series

To ensure preparation of samples and quotations suitable for your application, please provide the information below:

1. Fixation:

- Central thread (3/8"UNF) - With fixing nut (optional) (mod. ECR 02)

- Two screws (Nr 8 - 32 UNC) (mod. and ECR 02)

- Two self-tapping screws Ø 3,5mm (mod. ECR 03)

2. Load:

- resistive: voltage and current

- inductive: voltage, current and power factor

3. Application:

- equipment on which it will be applied

- number of positions and geometric arrangements (provide panel layout)

- shaft dimensions (preferably provide the knob)

- electrical diagram (internal connections depending on position and geometric angle)

- service life: in test cycles and conditions

- temperature range to which it is exposed

- specific operating conditions

- test specifications

4. Estimated monthly consumption

5. Quantity and delivery date of samples or estimated production start date

Note: Whenever possible, provide the equipment in which it will be applied and the test conditions that are necessary.

ETM and TLC series

To ensure preparation of samples and quotations suitable for your application, please provide the information below:

1. End of scale timing and tolerance (standard models: 1 minute, 15 minutes, 30 minutes, 1 hour, 2 hours, and 9 hours, with 5% tolerance) - provide dashboard layout

2. Direction of rotation:

- TLC - time

- ETM - clockwise and counterclockwise

3. Food:

- 110/120 Vac - 60 Hz;

- 220/240 Vac - 60 Hz;

- 220/240 Vac - 50 Hz

4. Contacts:

Load: - resistive: voltage and current

- inductive: voltage, current and power factor

5. Fixation:

ETM:

- Self-tapping screw 2,9

- W screw 5/32" x 1/4"

- Screw M 4 x 6mm TLC:

- Self-tapping screw 4

6. Applications:

- equipment on which it will be applied

- shaft dimensions (preferably provide the knob)

- power cables

- electrical diagram (diagram of contact situation in time)

- service life: in test cycles and conditions

- temperature range to which it is exposed

- specific operating conditions

- test specifications

7. Estimated monthly consumption

Quantity and delivery date of samples or estimated production start date

Note: Whenever possible, provide the equipment in which it will be applied and the special test conditions that are necessary.

Didn't find what you need?

Contact us using the form below, we can develop your product!