Emicol has just given training on Lean Six Sigma Green Belt (statistical process control) to 24 of its employees, with the aim of eliminating failures and optimizing processes in all areas of the company. These collaborators, who went through a selection process with the application of tests, where we had more than 100 candidates registered from the most diverse areas of the company, where the 24 best positioned, within the criteria of the program, were chosen.

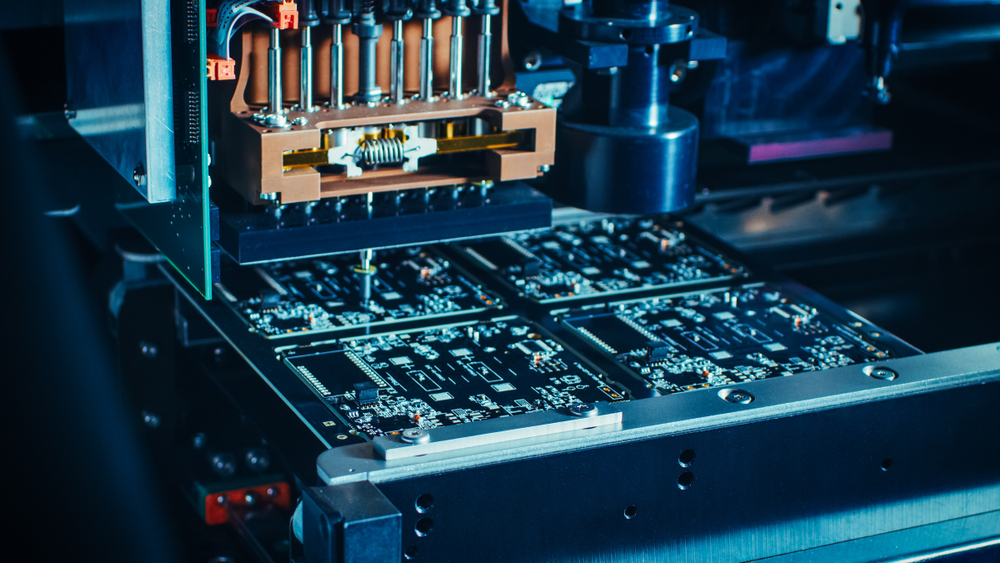

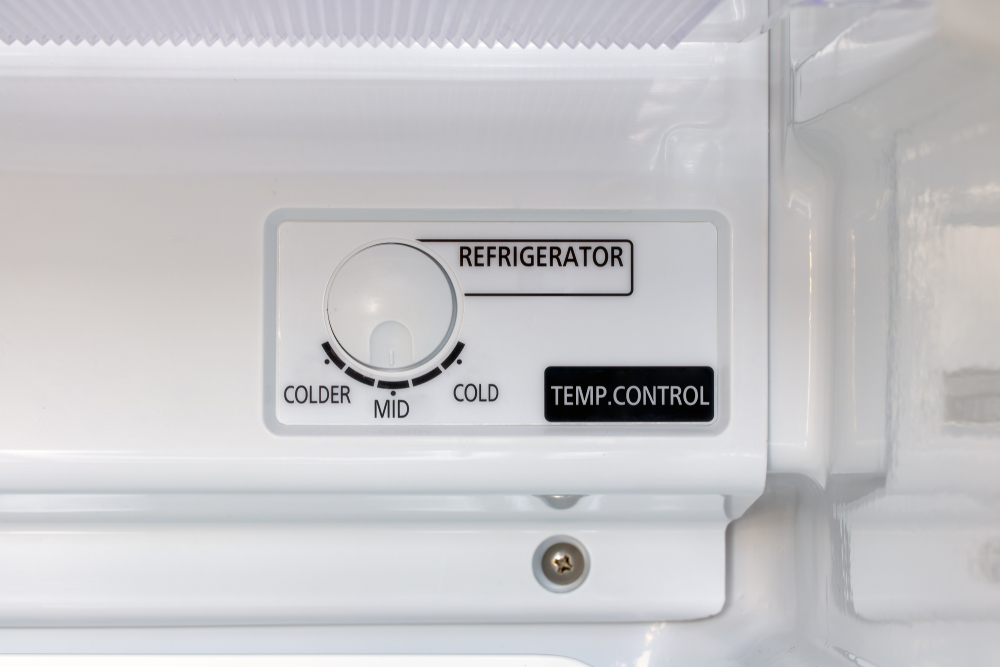

The methodology is part of the Continuous Improvement Program of the manufacturer of electromechanical and electronic parts and components, for home appliances, automotive and other segments.

Since 2016, Emicol Eletro Eletrônica, from Itu (SP) started an internal program to train professionals and improve processes and reduce failures. The company already has 11 Black Belts in Lean Six Sigma and this has been recognized by some of its clients, as well as participation in several national awards for events on the subject.

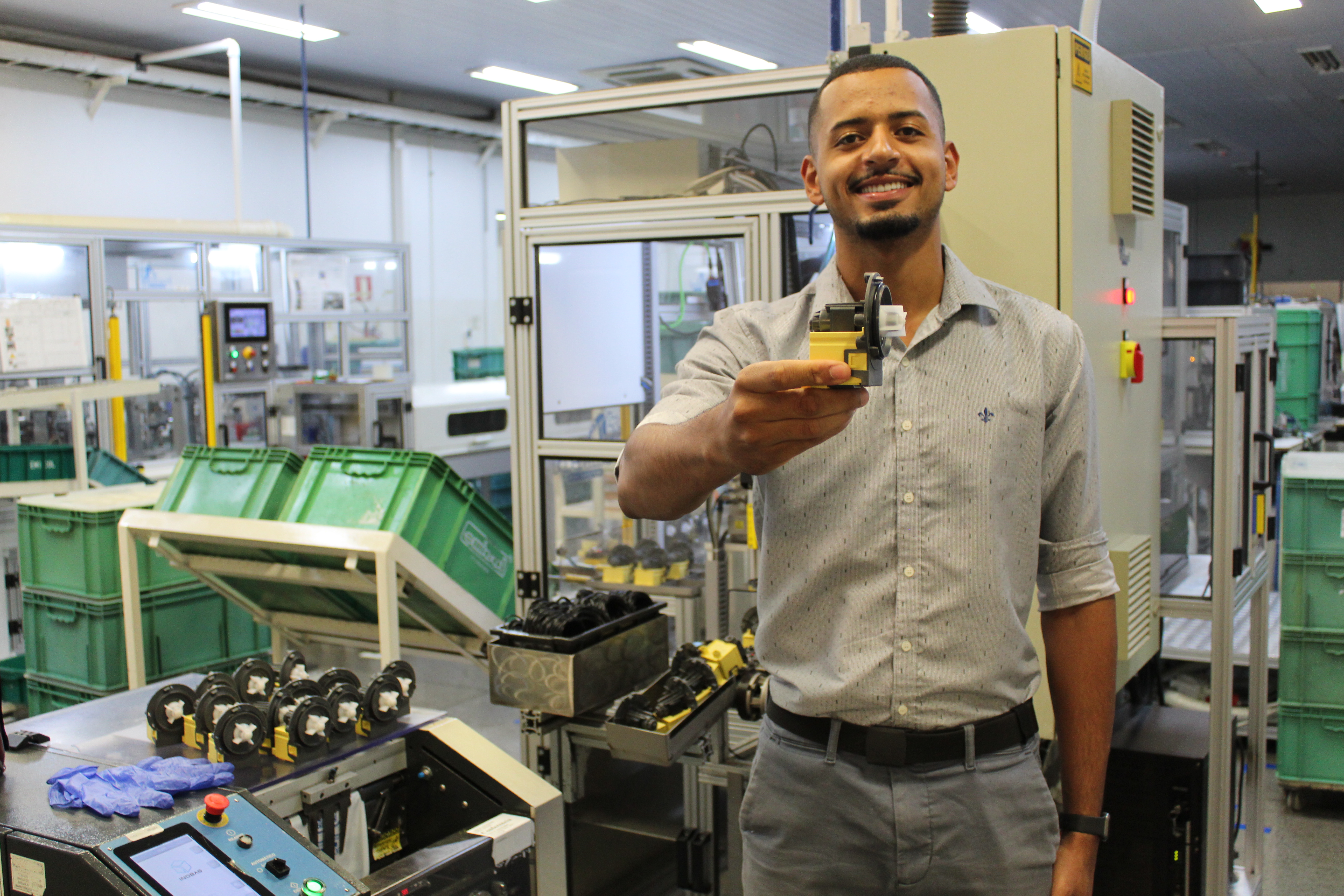

Employees participated in the Lean Six Sigma Black Belt training

To help these professionals and develop a culture of zero defects, during the recess period (December 20th to January 7th), Emicol, in partnership with the consultancy Bacellar Trainings, trained 24 of its employees in the Green Belt methodology. The course had collaborators from the areas of research and development, industrial engineering, logistics, maintenance, tooling, continuous improvement, human resources, metrology and production.

As next steps, each employee must prepare a project using the techniques taught in the course in order to obtain certification. Each of the projects is different, but they all have cost reduction, quality improvement or resource optimization objectives.

So far, the Belts have achieved results in 10 projects aimed at reducing costs in the manufacturing process, three projects aimed at improving product quality and two projects to standardize the systematic of administrative procedures.

Six Sigma or Six Sigma is a set of practices originally developed by Motorola to systematically improve processes by eliminating defects.

Six Sigma can also be defined as a planned management strategy, focused on quality and financial results, with the objective of promoting significant changes in organizations, always seeking improvements in processes, products and services offered to customers.

About Emicol

Emicol is a Brazilian company engaged in the development, production and sale of solutions in electromechanical and electronic controls and components, injection and over-injection of plastic and light stampings for home appliances, automotive and various other segments. It has production units in Brazil and Mexico and exports to over 30 countries and has been in existence for 50 years.

The company's industrial park, in the city of Itu (100 km from São Paulo), has approximately 30.000 m² of manufacturing area, where an extensive and varied range of items are manufactured in more than a hundred production cells, enabling Emicol to offer increasingly complete solutions for its customers, a factor that sets it apart from most of its competitors.

Contact:

- Website: emicol.com

- Facebook: facebook.com/emicolbrasil/

- Instagram: instagram.com/emicolbrasil/

- Linkedin: linkedin.com/company/emicol-brasil/